Fabrication

Our Process:

Design and Engineering: Using detailed CAD drawings to design the skid, ensuring it meets specific project requirements, load capacity, environmental conditions, and industry standards.

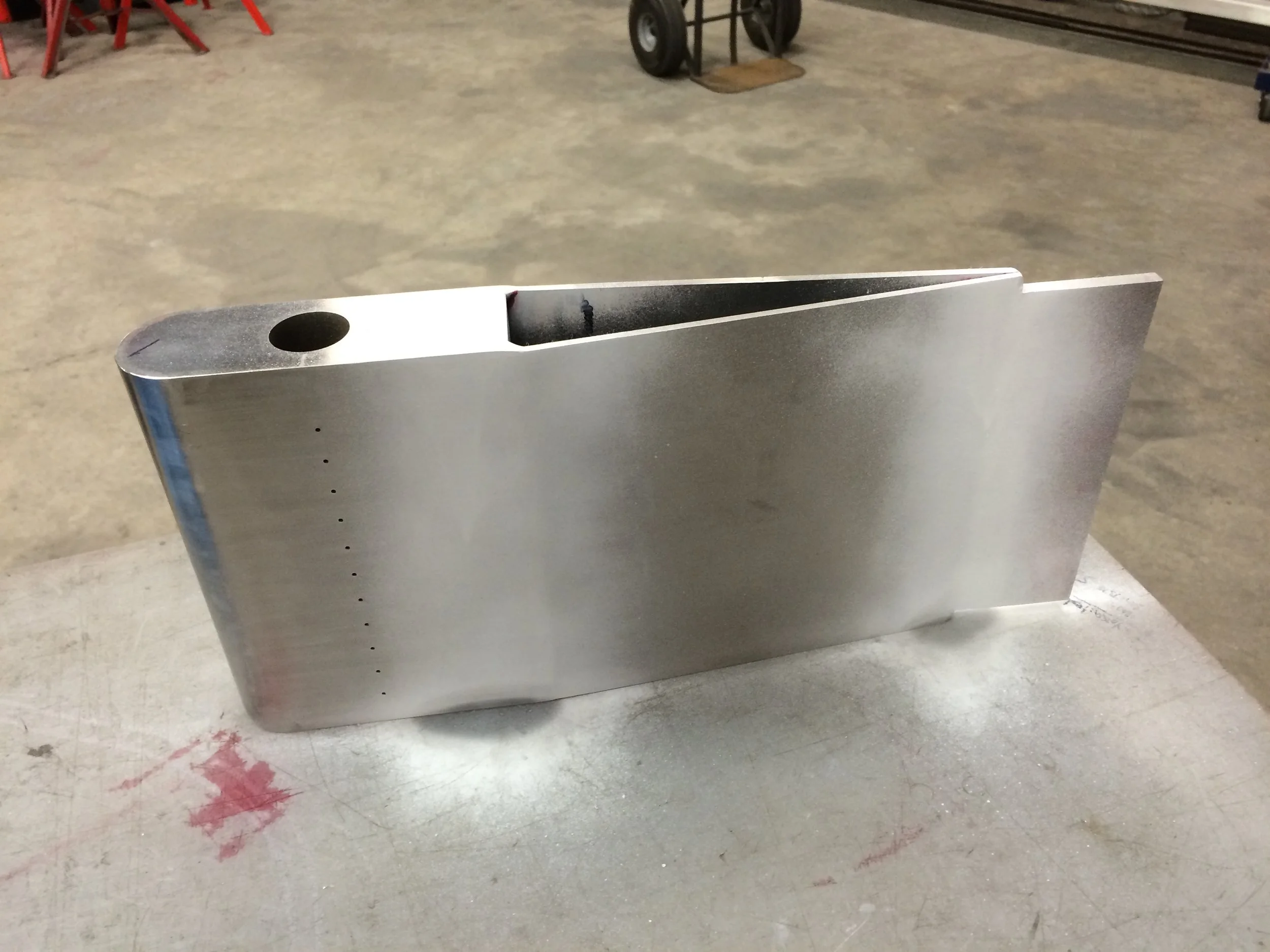

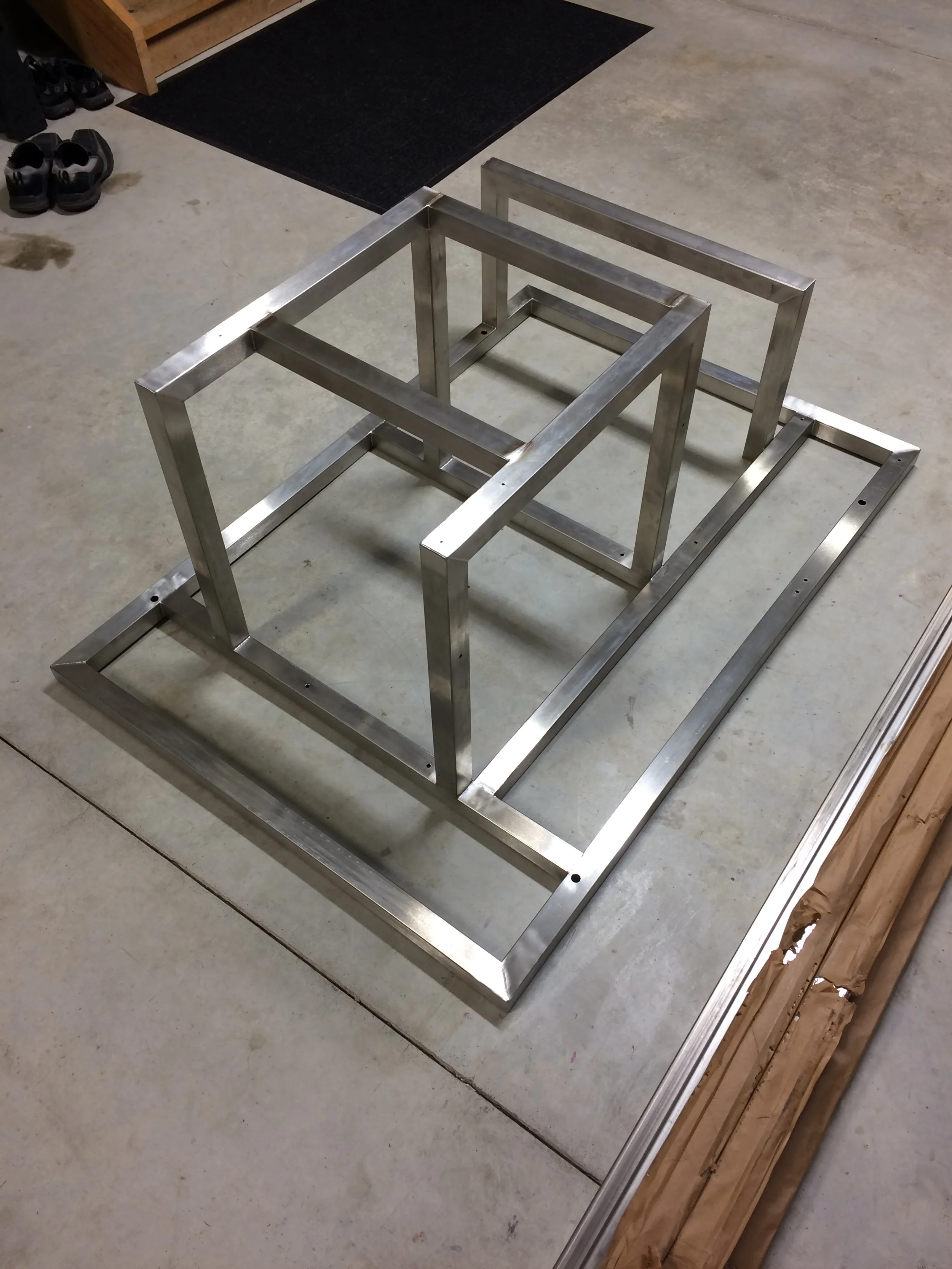

Material Selection and Procurement: Materials, usually industrial-grade steel or stainless steel, are selected for strength and corrosion resistance. They are sourced and quality-checked.

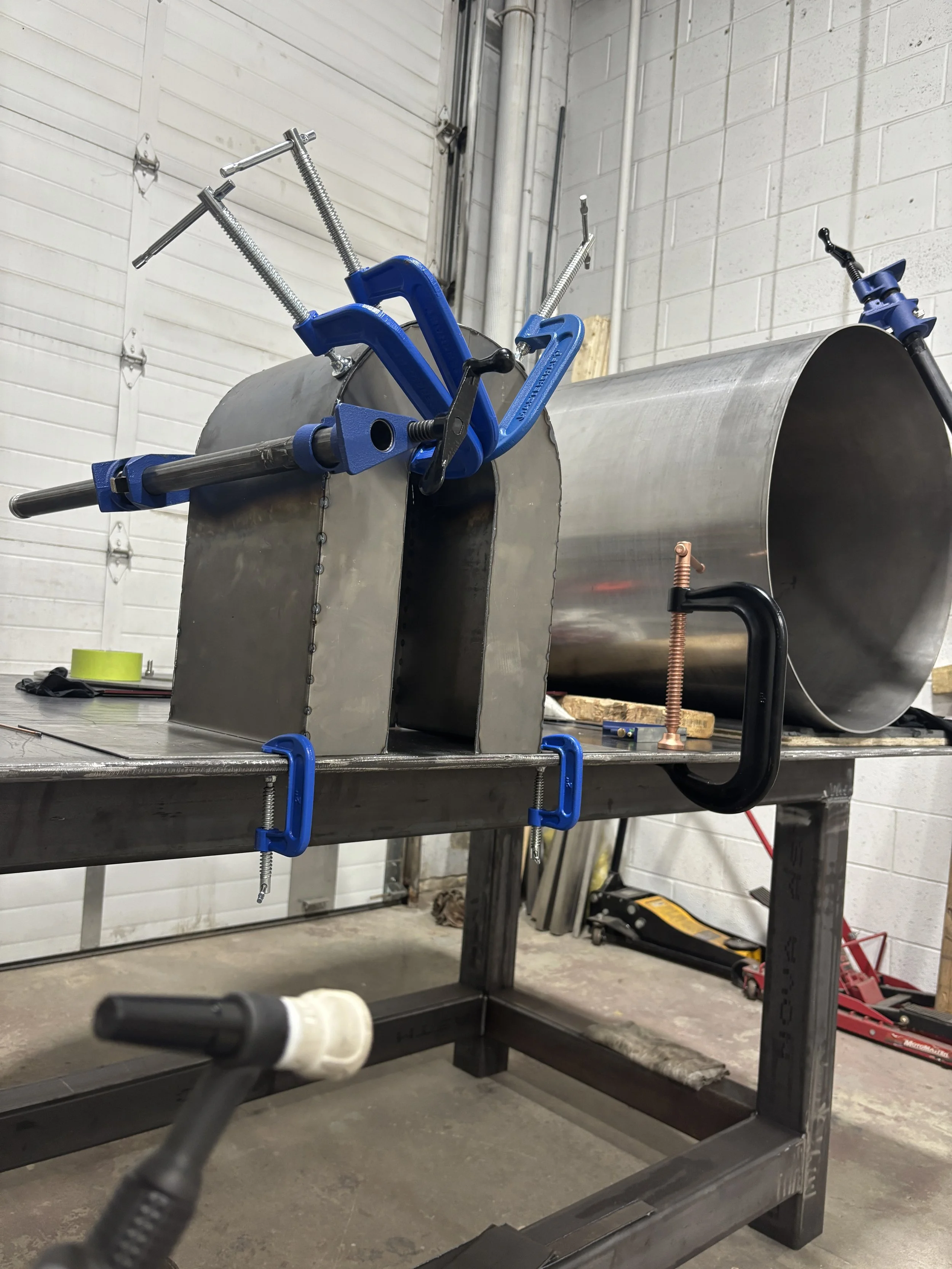

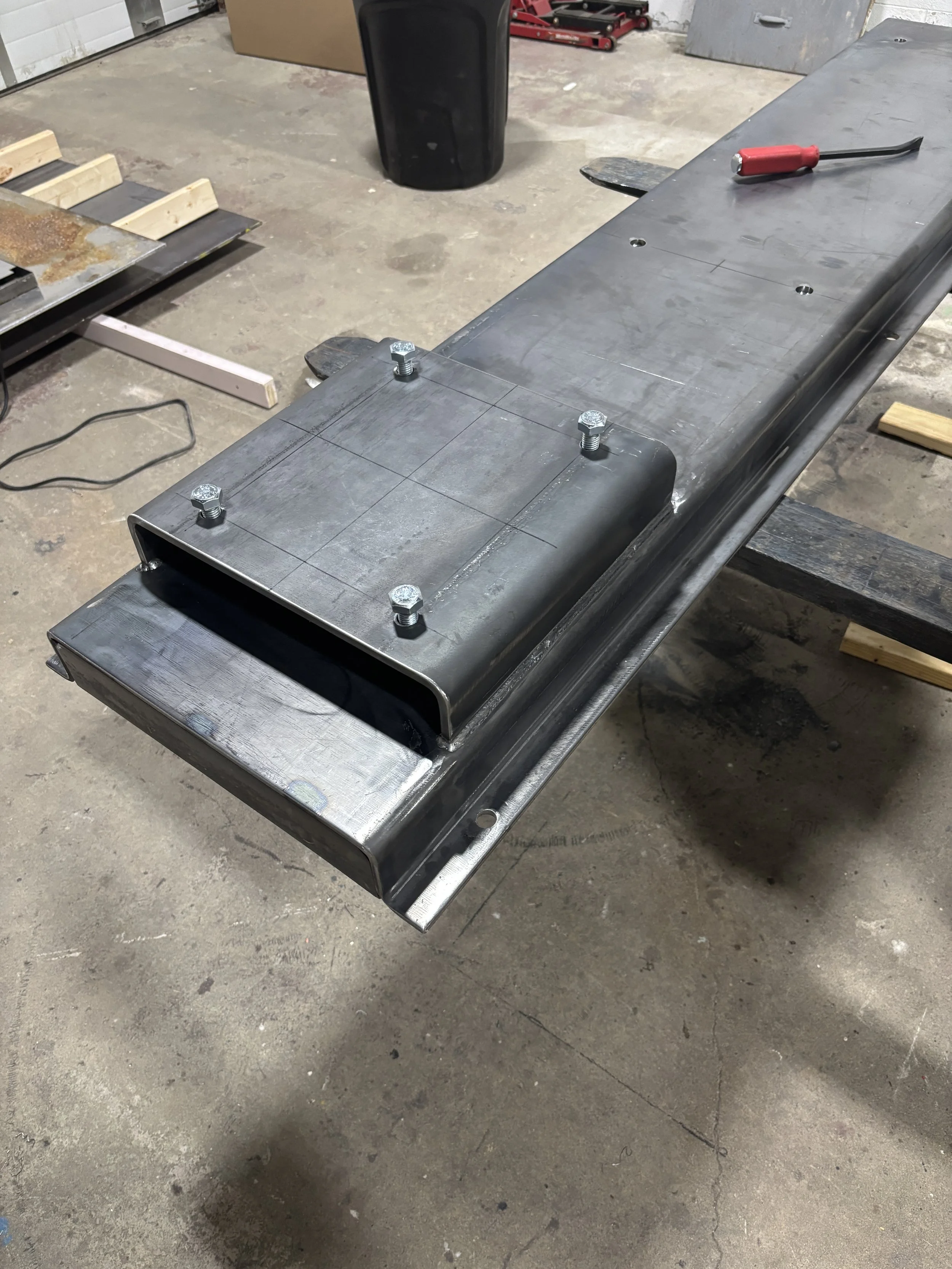

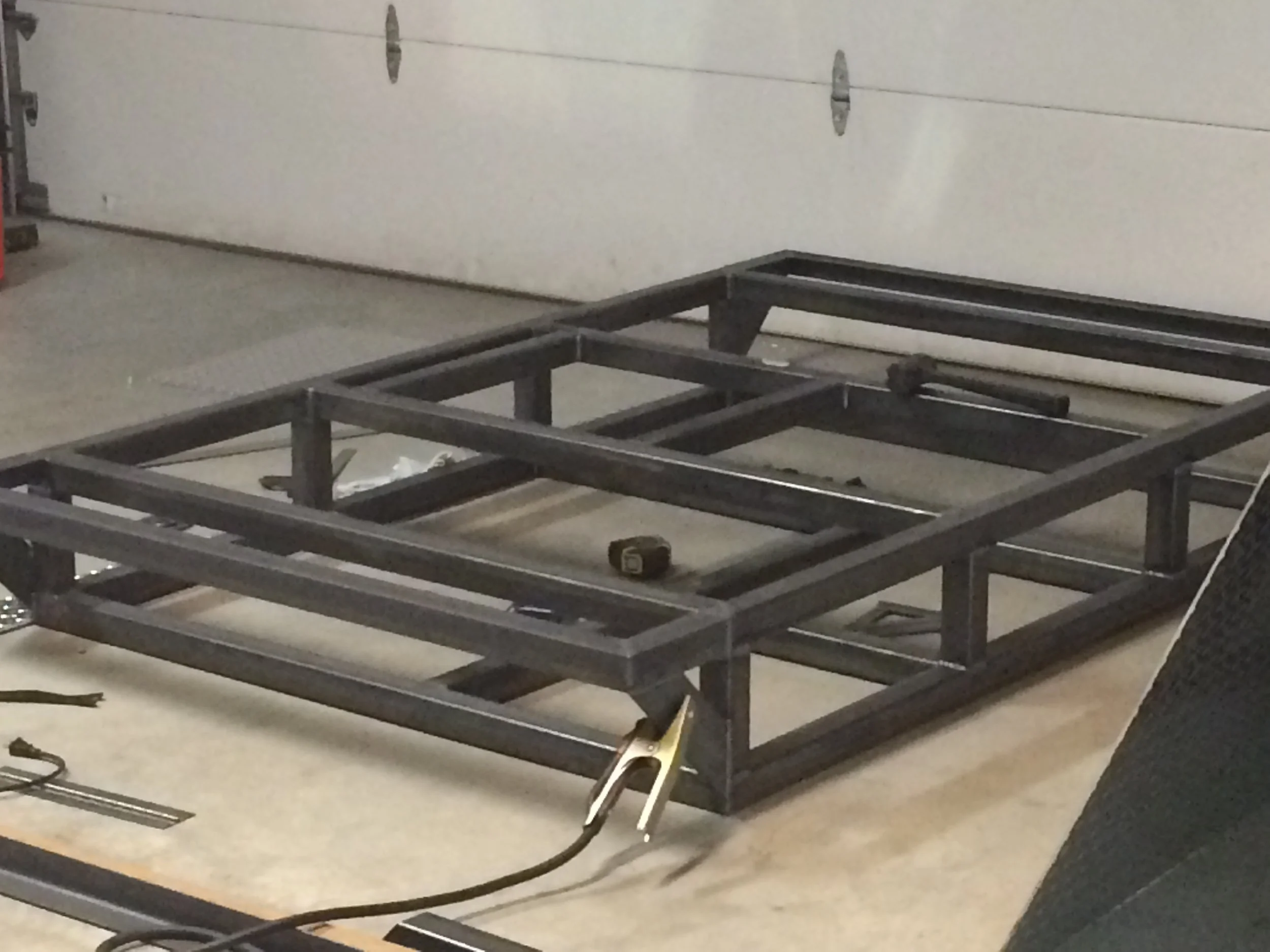

Structural Fabrication: This stage involves cutting, machining, and welding the base frame components to create the main support structure.

Component Assembly: The various components, such as pumps, valves, piping, instruments, and control units, are precisely assembled and integrated onto the steel frame according to the design.

Welding and Joining: Modern welding techniques are employed to ensure high-quality, leak-proof joints, which is especially important for sanitary or high-pressure applications.

Surface Finishing: The fabricated skid often undergoes finishing processes like cleaning, polishing, or painting to protect the steel from corrosion and meet hygiene standards.

Testing and Inspection: The complete, assembled pump skid undergoes rigorous testing to ensure all components work seamlessly and safely before it is shipped to the final location.